Gary Wickham has shown us the finished product of his 48th scale Freedom models X-47B

UCAS build, but now it’s time to go to school and learn just how he

achieved the results you might have seen in the gallery

glamour shots. Let’s see how he did it in Pt I

Northrop Grumman

X-47B UCAS - Build Review Pt I.

Freedom Models (FD18001)

Scale: 1/48

Started: October 2014

Finished: January 2015

Available through Freedom Models Distributors Worldwide.

Built by Gary Wickham

Finished Gallery link

PT II Painting and finishing

Freedom Models (FD18001)

Scale: 1/48

Started: October 2014

Finished: January 2015

Available through Freedom Models Distributors Worldwide.

Built by Gary Wickham

Finished Gallery link

PT II Painting and finishing

The U.S. Navy’s X-47B Unmanned Combat AirSystem (UCAS)

program was designed to demonstrate the ability of a tailless, fighter-sized

unmanned aircraft to land on and be launched from the flight deck of a Navy

aircraft carrier while underway at sea, one of the most challenging aviation

environments.

Under a contract awarded in August 2007 by the U.S. Naval

Air Systems Command (NAVAIR), Northrop Grumman designed, produced and is flight

testing two autonomous, low-observable relevant demonstrator aircraft designated

the X-47B UCAS.

In 2013, the company used these aircraft to demonstrate the

following “firsts” for unmanned jet-powered aviation:

• First catapult

launch from the deck of an aircraft carrier

• First arrested

landing, or “trap,” on the deck of an aircraft carrier

Completion of these historical events meant that all carrier

demonstration objectives had been met. However, the Navy decided to keep the

X-47Bs fling to learn more about, and reduce risk for, unmanned carrier

aviation.

To date, the X-47B has conducted operations aboard three

different aircraft carriers: USS Harry S. Truman (CVN 75), USS George H.W. Bush

(CVN 77), and USS Theodore Roosevelt (CVN 71). In addition, the capability to

conduct autonomous aerial refuelling has been developed utilizing a surrogate

aircraft, in anticipation of demonstrating the refuelling of an X-47B in flight.

The successful X-47B flight test program is setting the

stage for the development of a more permanent, carrier based fleet of unmanned

aircraft.

Modelling Reference Material

During my build I discovered several online resources that you may find useful:

Photos, Videos and Reference Information about the X-47B

During my build I discovered several online resources that you may find useful:

Photos, Videos and Reference Information about the X-47B

- www.northropgrumman.com - Northrop Grumman Media site for

X-47 UCAS

- wikipedia.org

- Northrop Grumman X-47B

- youtube.com

- X-47B UCAS wireless ground handling demo

- youtube.com

- X-47B UCAS Flight Test Highlights (Summer 2011)

- youtube.com

- X-47B UCAS First Carrier-Based Flight + Touch & Go + Arrested

Landing

Other Online Model

Builds/Reviews of the Freedom Models X-47B UCAS kit

- Build on britmodeler.com by Mike

- Build

on zone-five.net by Patrick Spitaels

- Official Facebook page of Freedom Models EU

Thoughts on Building the Freedom Models X-47B UCAS...

Freedom Models is a relatively new entrant in the plastic

scale modelling market and for their debut kit they chose to model a subject

that I found both interesting and topical, the Northrop Grumman X-47B UCAS in

1/48.

As a kit, the X-47B has been done before in 1/72 by Platz

but never before in 1/48. Being an unmanned drone the X-47B seems (like most

unmanned aircraft) to polarise the modelling community into those that love it

and those that hate it. I definitely fall into the first camp. I find the

concept of both remote piloted and now autonomous combat/recon aircraft to be a

fascinating subject for modellers.

Upon first opening the box I noted that the main fuselage

parts had that subtle "orange peel" roughness to the surface. This I

have found is quite common with kits manufactured in China and is similar to

what you would find in recent Kittyhawk or Kinetic boxings. The roughness is

easily dealt with by some light sanding which is no drama on the X-47B as it’s

a very streamlined shape. Of course being a drone there is no cockpit to contend

with, which means the build proceeds a lot quicker than your more traditional

aircraft build. I found the general fit of the parts to be excellent requiring

little or no filler. A small photo etch fret is provided and unlike other

manufacturers, Freedom have sensibly provided parts in PE that make benefit

from the scale thinness afforded by brass which you just can't reproduce in

plastic, the wiring loom in the wingfold is a good example.

A feature of the kit that I thought was above average was the

instructions. I really like the way Freedom have provided clear diagrams of how

parts should be aligned to each other which is of great help when assembling

the model. Freedom have clearly done their homework and it shows in the

details. The inclusion of options to fold or unfold the wings, open of close

the bomb bays and several "what if" decal options for possible future

carrier deployments are testament to the effort that went into this kit by the

Freedom team.

If I had to pick one thing I would like to see Freedom

improve it would be the decals. Not in terms of accuracy (although I did smile

when I saw one of the stencils said "BEWERE OF BLAST") but in terms

of the thickness of the decal material itself. Compared to high quality decals

from the likes of Cartograf (which these days you get even in a $10 Airfix kit)

the box decals for the X-47B are very thick. The decals did perform well and

responded to setting solution but I found myself cutting away as much of the

thick clear carrier film as possible.

Overall I'd rate this kit an 8/10. It's an interesting

subject, it's been well researched, it's been properly engineered with sensible

parts breakdown and the assembly/painting instructions are clear.

The Build

The following photos and comments relate to my build of the

Freedom Models X-47B which I chose to model as the 2014 demonstrator used in

carrier trials. As the build is relatively simple I have taken a slightly

different path for this build report. Typically I document my builds in

chronological order (i.e. the order in which I do things, which is almost never

strictly as the instructions specify) but this time I have used the kit

assembly sequence as the ordering for the build report.

As a diehard aircraft modeller it feels odd starting a new

model and not doing the cockpit first. Step one however this time around was

the nose undercarriage. Options are provided for you to display the catapult

arm in the raised or lowered position. This is a by Freedom and lends itself to

those that want to display the model ready for a launch. I had other plans so

went with part E5 rather than E6.

There is room to add some detailing to the kit parts, mainly

in the form of cabling and hydraulic lines. As this picture shows, the nose

wheel strut is quite complicated (more so than normal aircraft I think) and

perhaps this is because of the extra gear required to remotely steer the

machine.

I added some small amount of details to the nose gear in the

form of lead wiring and enhanced some of the bolt heads using my Historex

Agents hex punch set. The PE tie down rings and the launch bar actuator

rods shown here are provided in the kit from Freedom.

A quick test fit of the completed nose gear assembly

confirmed that it could be left till the end to be fitted to the main airframe.

The undercarriage bays are pretty sparse but two things stopped me from adding

extra detail here: a) I had no useful reference photos and b) I have decided

that pouring hours into detailing parts that will almost never be seen on the

finished model is not productive.

Painting of the landing gear is pretty straightforward, a

black undercoat followed by a couple of coats of white (in my case Tamiya White

Primer which I find covers very well). The details were picked out by hand

using Vallejo paints and the chrome oleo strut is fitted with some Bare Metal

foil (Chrome)

A final oil wash of Davys Grey over the white sections

(landing gear, wheel well and wheel hub) completes this step.

Step 2 has two stages. Stage 2.1 deals with the right hand

main landing gear whilst 2.2 deals with the left. Optional Photo Etch tie down

rings can be used here. The correct alignment of part E21 for the right MLG

(and E20 on the left MLG) is best handled by dry fitting the main strut to the

undercarriage bay and then gluing part E21/E20 to the strut to ensure the

correct angle is achieved.

A good overall view of the undercarriage shows us the colours,

cabling details and general sit of the aircraft on the undercarriage. Never

trust a model manufacturer too much, always use your own reference to double

check even the most basic of things. Happily Freedom Models has done a good job

here.

Reference photos show us the location of hydraulic lines as

well as the use of colour variations in the lines themselves. This photo is

also useful to show the correct alignment of the bay doors when we get to that

point.

The main landing gear strut and main support had some

visible ejection pin marks that I dealt with using plastic card discs (glued

then sanded flush). Like the nose gear I have added some hydraulic lines from

0.3mm lead wire and assorted hex bolt heads using my Historex Agents punch set.

The kit tires have no tread (the real tires have a standard

tread pattern). MustHaveModels

have recently released a set of resin replacement wheels which do provide a

tread pattern.

Here we see the parts being test fitted in the wheel well.

The parts were left in place while the glue dried to ensure the correct angle

was achieved on the support strut (part E21).

With both MLGs complete a final test fit into the wheel

wells to make sure the general alignment is accurate and that both sides are

even, after all we don't want the finished model to sit lop-sided and now is

the best time to check so we can correct it if any problems are found.

During my recent builds I have taken to base coating

cockpits, wheel wells and assorted accessories (like landing gear) in black. It

may seem a little counter intuitive to prime a part that is to be white with

black but it actually works well because it helps to give the white some depth

rather than being too stark (which can happen to white if not toned down in

some fashion). For the X-47 landing gear I have used Tamiya NATO Black XF69.

A couple of coats of white have been applied to the landing

gear. I have been experimenting with different whites to see which one provides

the best coverage and for now have settled on Tamiya White Primer which is only

available in a rattle can. I don't like rattle cans and so prefer to decant the

cans contents into a normal bottle for use in my airbrush. The Tamiya White

Primer is very hardy and covers very well in only one or two applications which

means you don't need to build up several coats to avoid the transparent effect.

Once the white is dry it’s time for some final detail

painting on the landing gear. Vallejo paints are my favourite for brush

painting as seen here on the hydraulic lines. Most every modern aircraft has

some form of shock absorbing strut built into the landing gear. The piston in

the strut is often visible and typically a very shiny chrome finish. The best

way to simulate this I have found is to use a small strip of self-adhesive Bare-Metal Foil (Chrome)

wrapped around the strut. It's easy to use and looks very convincing. For metal

parts that need to be hand painted I like to use the metallic colours in the

Citadel paints range.

The wheels and tires have been painted (Tamiya Rubber Black

XF85 + Tamiya White Primer). I normally paint the black first then mask off the

hub with Tamiya tape cut using a circular scribing template and then apply the

white. The detail in the wheel hubs has been accentuated with a light wash of

Davy's Grey oil paint.

A view of the

finished port MLG fixed to the main airframe during final assembly.

Here we see all three landing gear assemblies fixed into

place on the final model. To ensure a very strong bond I like to use two part

epoxy glue for any load bearing parts like undercarriage.

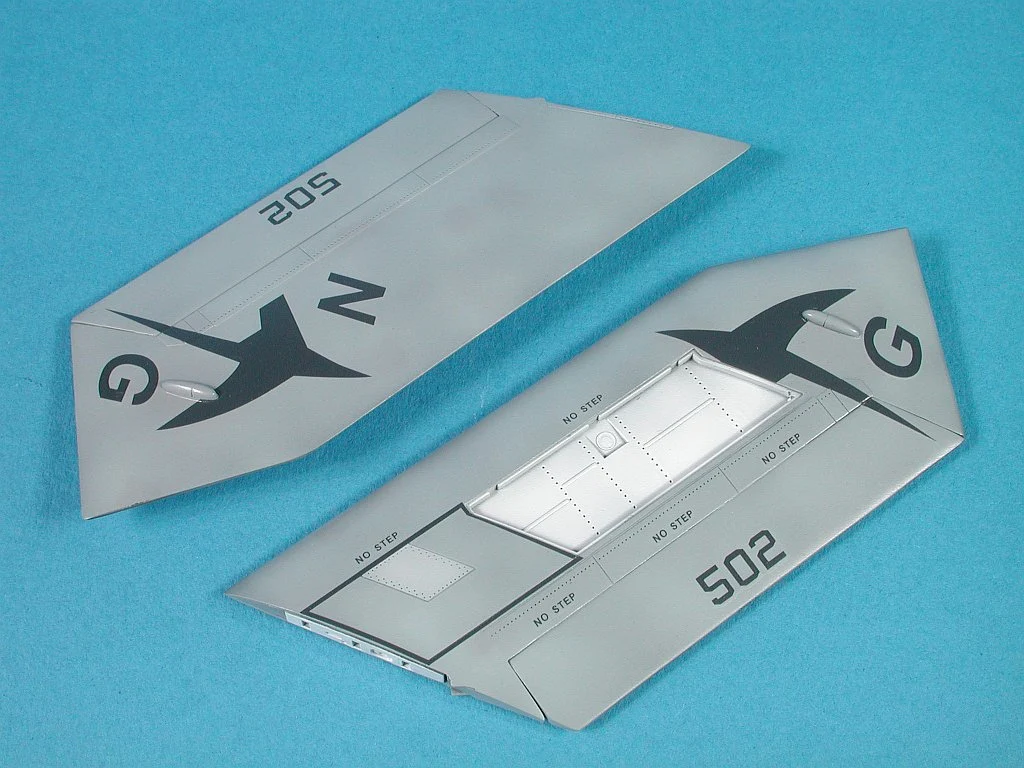

Steps 3.1 and 3.2 cover off the assembly of the left and

right wings. Due to the unique shape of the X-47's fuselage the wings

themselves are quite stubby. Air brakes (or spoilers) are fitted to the top of

each wing and when the wings are folded the airbrakes droop open with gravity

making for an interesting feature on the model.

A useful study of the wings in the folded position. Note

that because power is applied the hydraulic systems are pressurised and the air

brakes are closed. When powered down the air brakes open with gravity and hang

down below the folded wings.

Both wings are easily assembled with a minimum of fuss. The

fit is good and only the seams on the edges need sanding when dry. The ailerons

seem to always be in the neutral position and the inner end of the wing

contains the support bracket for the wing-fold. If you plan to display the

wings unfolded be sure to consult the instructions as the parts needed are

different than shown here.

A close in view of the port wing upper surface. Note the

small circular PE disc in the centre of the air brake recess. I am not sure why

Freedom provided this as PE because it is used to cover a hole in the recess

which I assume was originally moulded inaccurately (perhaps for an actuator??)

and rather than remove it they simply provided a cover in PE. Also note that I

have filled the panel line on the aileron. I repeated this on both top and

bottom of both ailerons and flaps. Based on photos of the real X-47 I could not

see evidence of any panel lines here.

The air brake recess and wing-fold have been masked and

sprayed with Tamiya Primer White.

Painting and decaling on the wings is now complete. It’s a

pity that with the wings folded most of the nice detail provided here will be

hard to see on the finished model. Its a good addition by Freedom that the

decals which touch the navigation lights have a small cut out which helps to

position the decal correctly and means you do not have to fuss around with

getting the decal to sit over the raised detail. The only final touches needed

on these parts are to paint the navigation lights (Mr Color Clear Red and

Green) and apply some weathering (with pastel chalk) to the leading edge of the

ailerons to simulate wear and tear of the moving parts.

Here we see the folded wings on the finished model. Note the

open air brake and the pastel chalk weathering applied to the front of the

aileron. This weathering is to simulate scuff marks left by the movement of the

aileron in flight.

A good shot of the wings showing the folded angles as well

as the red and green nav lights on the tips.

Step 4 involves the assembly of the intake and exhaust

trunking. This configuration is about as simple as it gets for jet aircraft

models with a top and bottom and two internal "plugs" for the front

and rear of the engine.

From experience I know that it will be virtually impossible

to mask this type of intake once the parts are assembled. Instead I have

pre-painted the bottom portion of the intake trunking and pre-masked it. I now

need to make sure that when I glue the top and bottom (C1 to B1) together that

I do not get any glue seeping inside (to ruin the paint). The front face of the

engine has been painted Alclad Aluminium and the rear section of the exhaust

painted basic black.

Rather than follow the assembly sequence in the instructions

to the letter it was now that I deviated based on experience. I knew that if I

glued the intake parts together at this point and then tried to mate them to

the fuselage it would be challenging to get a clean join. So instead I first glued

the top of the intake (part C1) to the upper fuselage (part A1). This allowed

me easy access to clean up, paint and mask this area prior to mating the bottom

of the intake trunking and then closing up the fuselage. Step 1 is to glue and

fill the seam between the parts C1 and A1. Tamiya Basic Putty does the job.

Step 2 is to sand the seam and check with a coat of grey

primer (Alclad Grey primer in my case).

Step 3 is to paint the interior white and then mask off

using Tamiya tape. This assembly is now ready for mating with parts B1 and then

to A3.

Step 5.1 involves mating the intake/exhaust assembly with

the fuselage and closing it all up.

The shape and contours of the nose of the X-47B is quite

distinctive. To minimise radar reflections it is desirable to eliminate all

panel lines or sharp edges on the nose. The kit seems to accurately reproduce

the complex compound curves of the area in and around the intake inlet.

The fit of part B1 to the triangular hole in the top

fuselage is pretty good but the lip on the intake part does not allow it to

rise up enough to meet the fuselage and a small step is the result. No panel

lines or steps are evident on the real aircraft so I needed to do some

adjusting and trimming here to eliminate as much of the step as possible before

gluing.

The first task in minimising the step is to remove the

alignment lip from the intake part. With this removed it is possible to now

lift the part up higher to better match up with the forward fuselage. It would

be possible to just glue the two together and then use filler to eradicate the

step but that somehow seems like even more work.

With the lip removed it’s time to join the lower intake (B1)

to the upper fuselage. As I had already painted the interior of the intake and

exhaust trunking I did not want to risk the chance of any glue seeping inside

of the join and potentially ruin the paint. So rather than running glue along

the join like I normally would do I used a series of plasticard braces along

the length of the two parts to glue them together. These braces had the glue on

them and therefore I did not need to apply glue to the seam itself. It seemed

to work ok so score one for lateral thinking I guess.

With the nose parts now glued together I needed to sand the

curved nose section in front of the intake to match the contours of the real

aircraft. This photo provides a good side view of what this needs to look like.

After much sanding and a little filling with super glue and

a strip of 10thou card the nose cross section looked about right to me. The

seams and panel lines were removed completely from the section of the model.

This angle shows how the pre-masked intake interior looked

after the parts were mated together. I have used some damp tissue paper to fill

up the intake hole and act as a cheap masking material. A small amount of

Milliput has been used on the very front of the join to blend the top and

bottom together. Take a moment and imagine how difficult would be to achieve

this masking once the intake was assembled like this ...

Many times its only under a coat or primer that we really

find out how our efforts have turned out. I was very happy with how the shaping

of the nose curves had ended up. Notice that I have rounded out the curve at

the very front of the bulge. This was much more pointed out of the box which

did not match up well with photos of the aircraft.

With all the nose work complete to my satisfaction it was

time to glue the top and bottom fuselage parts together. She was finally

starting to look like an X-47. The fit was very good and the clamps are really

only needed as a precaution while the glue sets.

The exhaust was masked after assembly mainly because it was

far more accessible than the intake would have been. This will be later sprayed

with Alcald metalizer and masked off prior to main painting.

Steps 5.2 and 5.3

cover the assembly of the landing gear bay doors.

Each hinge bracket is supplied as a separate part which are

glued to the relevant door. Proceed carefully here as many of the parts look

the same but have subtly different angles that can impact the fit and alignment

of the door when attached to main airframe later on. To assist with holding the

parts for painting I like to use some Tamiya tape wrapped to form double sided

tape. This is stuck to some spare cardboard and the door then stuck to the

tape. Very solid and alleviates the mess.

Being a USN aircraft the gear bays are white and so is the

inside of the doors. First step is to paint them white (again Tamiya White

Primer has been used).

Another feature of most USN aircraft is the use of safety

red on the edges of all gear doors (and often other protruding airframe parts).

A light coat of red was applied over the white around the edges. This red was

subsequently masked off and the white was touched up to cover the red overspray.

The finished gear doors make a colourful addition to the otherwise

very grey model.

Step 5.4 focuses on the assembly of the lower antennae and

gear bay details (such as they are). Parts E8 (left & right) are installed

in the main gear bays and provide the attachment points for the support struts

on the landing gear themselves.

With all the relevant antennae attached to the lower surface

(at the appropriate angle to the fuselage) I also spent a little time adding

some ribbing detail to the tail hook bay. This just looked so bare that I felt

it needed something so I used my imagination as no picture showing the interior

were available.

Step 5.4 continues with the remainder of the lower surfaces

assembly. If like me you plan to close the bomb bay doors now is the time to do

that. The flaps can be attached and I preferred to leave the undercarriage

legs/ doors plus the tail hook off until all major painting was complete. As

mentioned at the start of this article I like the attention to detail that

Freedom has included in the instructions by providing the small callout diagrams

on the side showing mostly how things should be aligned and close-ups of how

things fit together. This helps take the guess work out. One tip I would offer

is that you should also leave the two pitots (E3 or P1 in photo etch) off until

the very end as they are very prone to breakage (don't ask me how I know this).

I captured this photo from a YouTube video of the tail-hook

testing. It was about the only way I could get at least some form of reference.

Notice the wiring attached to the surface of the hook body. Also note that the

tail-hook bay is not painted white (well it does not look white to me in this

or any of the other photos I could find).

Another photo captured from a video. This time the X-47

control surfaces are being put thru a self-test and as the flaps are fully

deployed I hit pause. Notice the 3 white sections on the leading edge of the

flap which are very visible when its extended. My guess is that these

correspond to the hinge points on the flap. As I planned to drop the flaps on

my X-47 I wanted to try and re-produce this interesting detail.

The fit of the bomb bay doors was pretty good, especially

considering the complex curvature of these parts. Freedom did a good job of

getting this right. Still, I found that the gap at the rear join on both bomb

bay doors was too wide for my taste and so I filled the join with super glue

and then re-scribed the panel lines. Here you can see I am using my favourite

Pactra vinyl tape as a guide for the scriber.

I did not want to "go to town" on the tail-hook

but decided that some effort was warranted as I planned to show the hook in the

down position. Here you can see some 0.3mm lead wire attached to the hook and

the hook being test fitted to the airframe. This view also affords us a good

shot of the basic ribbing I created inside the bay itself to add a little

interest.

Like the ailerons, I filled the panel lines on the flap and

then used some Verlinden scribing templates to help create the three hinge

covers as seen in the photo above. These would later be painted white and

weathered to match photos of the X-47.

The tail-hook has yet to have the cabling painted but the

base white has been done. The black bands on the rear section are actually

decals supplied in the kit. I used these instead of masking and spraying black

because I thought it would give me a better result. Trying to mask the small

undercut edges of the part would have been quite challenging.

Part II – the conclusion

of Gary’s build will be on our pages in a day or so, so keep on the lookout for

how the kit really goes together in PT.II

A very big thanks to Freedom models for sending this kit

to Gary to build it up and show you..

Gary Wickham.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)