Andy Moore has immersed himself into the build sequence after the In-box review of Takom's M3 Lee to show you how the kit goes together. He included some great tips & tricks you might want to use on your own build. See how it went together in his second article...

Construction Guide: M3 Lee Early – US Medium Tank

Manufacturer – Takom

Kit Number - 2085

Scale - 1/35

Price - ¥4,640 • $43 • £32 • €36 from Hobbylink Japan

After the in-box review of Takom's new M3 Lee, I was very much looking forward to getting stuck into the build. The subject is definitely one that appeals to me, with its pre-WWII boilerplate looks. One thing was concerning me though, as a few online comments from other modellers who have already tackled the kit, seemed to indicate there could be some fit issues, particularly with the upper hull panels. Well, the best way to find out is to build it, so time to get started.

The build gets underway with the lower hull, which is a very nicely detailed single-part moulding onto which the separate end plates are added. These both fit very well, although, in the case of the front transmission cover, I added a strip of plastic card on the inside of the hull to reinforce the lower joint.

It's probably not necessary, but I routinely add reinforcements to butt joints like this on most builds just to be on the safe side.

The final drive covers are added next, and Takom has given the inner sides of these a very realistic cast texture. Unfortunately, due to the way the parts are moulded, the texture couldn't be added to the front edges of covers. This is a simple thing to add though, using Gunze Mr Surfacer, stippled onto the outer edge of the parts, and slightly over onto the sides to blend in with the moulded texture.

With the lower hull built up, I got started on the running gear, beginning with the wheels. Since they're just single part mouldings, they are very quick to deal with, needing only the sprue gates to be cleaned up and a little wear and tear added to the rubber tyres.

The idler wheels are also essentially single part mouldings, but they do need a separate rim added, and the fit on the rims was a little gappy here and there. Nothing a little filler couldn't deal with though, and having the separate rims does give a more realistic appearance.

The main suspension bogies are built up from quite a few parts, which does make them quite fiddly to get together, and you need to be careful with the glue, as many of the parts are designed to remain articulated.

The swing arms for the main wheels need additional bolts adding, and Takom has provided these on the main sprue. Just slice them off and glue them in place.

Once built up, the bogies remain fully articulated. Now, you may be asking yourself “why would I need articulated running gear on a model with link and length tracks?” Well, it might seem odd at first, but it does make some sense. If you choose to replace the tracks with after-market working links, they'll conform to them, and to any groundwork you place the model on, without any modification. Even if you're just using the kit tracks, there'll be no worry about getting a wheel hanging in the air due to misaligned suspension. The articulated bogies will naturally sit level.

I normally like to keep road wheels separate for painting, but that's not really an option here. You could leave the bogies off altogether until the lower hull is painted, but actually, the access for painting/weathering isn't too bad with them in place. Having them in place at this stage also make building up and test fitting the link and length tracks a little easier too. As you can probably see in the photo, I added a little cast texture to the main suspension mounts using Gunze Dissolved Putty. I didn't want the texture to be too strong on the suspension units, and the Dissolved Putty is a little subtler than Surfacer when used for texturing. The suspension was still articulated at this stage, but later on, I decided to fix it permanently by placing the model on a flat surface, ensuring all the wheels were touching the ground, then running some Tamiya Extra Thin cement into the joints in the swing arms.

While I had the Dissolved Putty out for the suspension mounts, I also textured the transmission cover on the front of the hull. Again, I didn't want the texture to be too strong, particularly as I didn't want to lose the very finely moulded casting numbers. Don't be tempted to sand off the ridges running around the edges of two curved brackets on the cover, thinking that they're mould lines. They're meant to be there, as it's where the three sections of the transmission cover bolt together.

I decided to take a look at the tracks before continuing with the hull. Takom have provided a simple jig to set the slight sag after the drive sprocket on the top run. The main section of the top run is a single length, to which six single links are added to form the up-sweep at the end.

These are glued together then dropped into place on the jig. The only problem is the guide horns on the tracks are deeper than the jig, so with the jig sitting on the bench, the tracks won't drop fully down onto it.

To solve the problem, the jig just needed to be raised up a little. To do that, I glued some scrap strips of thin styrene to the back of the jig, which left enough clearance for the tracks to fully drop into place.

With the upper runs finished, I glued the five individual links that form the wrap-around sections at each end, directly to the drive sprocket and idler. I'll be leaving the lower runoff for painting, then I'll hopefully be able to piece the sections together at the end. That's the plan anyway. We'll see how well it works out when I get onto the painting, as sometimes link and length tracks can end up being too short or too long, and require some jiggling to get them to fit. As I say, we'll see how it goes when I get to that stage.

With the tracks taken care of (for now), I could get back to the main hull, and this is where I'd need to see if those early reports of poor fit were true. Before starting on the main side panels, I had to fit the front fenders, and these did confuse me for a moment, as the instructions aren't completely clear as to how they attach. I finally figured out that they slid under the hull overhangs, and butted up to a small tab on the underside. Once you work out how they attach, the fit is excellent.

I now started on the main upper hull, and the first sections to go on were the side panels. The most important thing here is to ensure they sit perfectly vertical, although where they connect to the rear plate helps a lot in keeping them straight. After that, the angled front corner panel was attached, and this seemed to line up just fine. There was a tiny gap where the very tip of that panel met the transmission cover, but that could be dealt with easily. With all these panels, I did give the mating edges a quick sand with a medium grade sanding stick, partly to ensure there was no flash or other imperfections to hinder the fit, and also because the slightly roughened surface would bond together better.

Next up were the front hull plates, and these were a little more troublesome to fit. The front plates themselves went on fine, but it was hard to get them to meet up with the previously attached corner plate. I think this was mainly down to the side plate pulling the corner plate very slightly out of alignment. That's why it's so important to make sure the side panels are vertical. The gap it left was quite small though, and the problem was easily solved by pulling the side panel in until the gap between the corner and front panels closed up. The side panel was held in with tape until the glue had dried.

The armoured surround for the gun was attached next. This fitted fine where it met the right hand side panel, but it didn't want to fully clip into place where it met the angle of the front plate. After examining the part, I realised it was the tab that holds the surround in place that was slightly pulling it out of position.

I trimmed some plastic from the ends of the tab which allowed some adjustment when it was in place, and after that the part fitted fine. I found that trimming these attachment tabs down helped many of the parts fit better. The way they come, the tolerances are just a little too tight.

The hull roof needs a slim panel fitting to form the back edge of the main fighting compartment. Takom have supplied this as a single piece that needs to be bent along two 'V' sections to form the correct angles. We've seen this method used by other manufacturers, and it's one that works well, and means there's two less corners to align.

Before the roof plate can be added, the main gun needs to be built up and installed. For this build, I'd decided to pick up some after-market metal barrels from RB Model (set 35B74), since the 37mm turret barrel was damaged in my kit.

The kit's main barrel was fine, but the after-market set I'd got had both the main and turret barrels included, so I thought I may as well use them both. The kit barrel is a one-piece moulding, and doesn't require much work apart from having the separate muzzle adding. The metal replacement does make a nice addition though, featuring some very fine rifling. The gun mount only needed to be drilled a little deeper for the metal barrel to fit. Takom have included an optional counterweight for the end of the barrel and, with a little modification, this could be used with the metal one too.

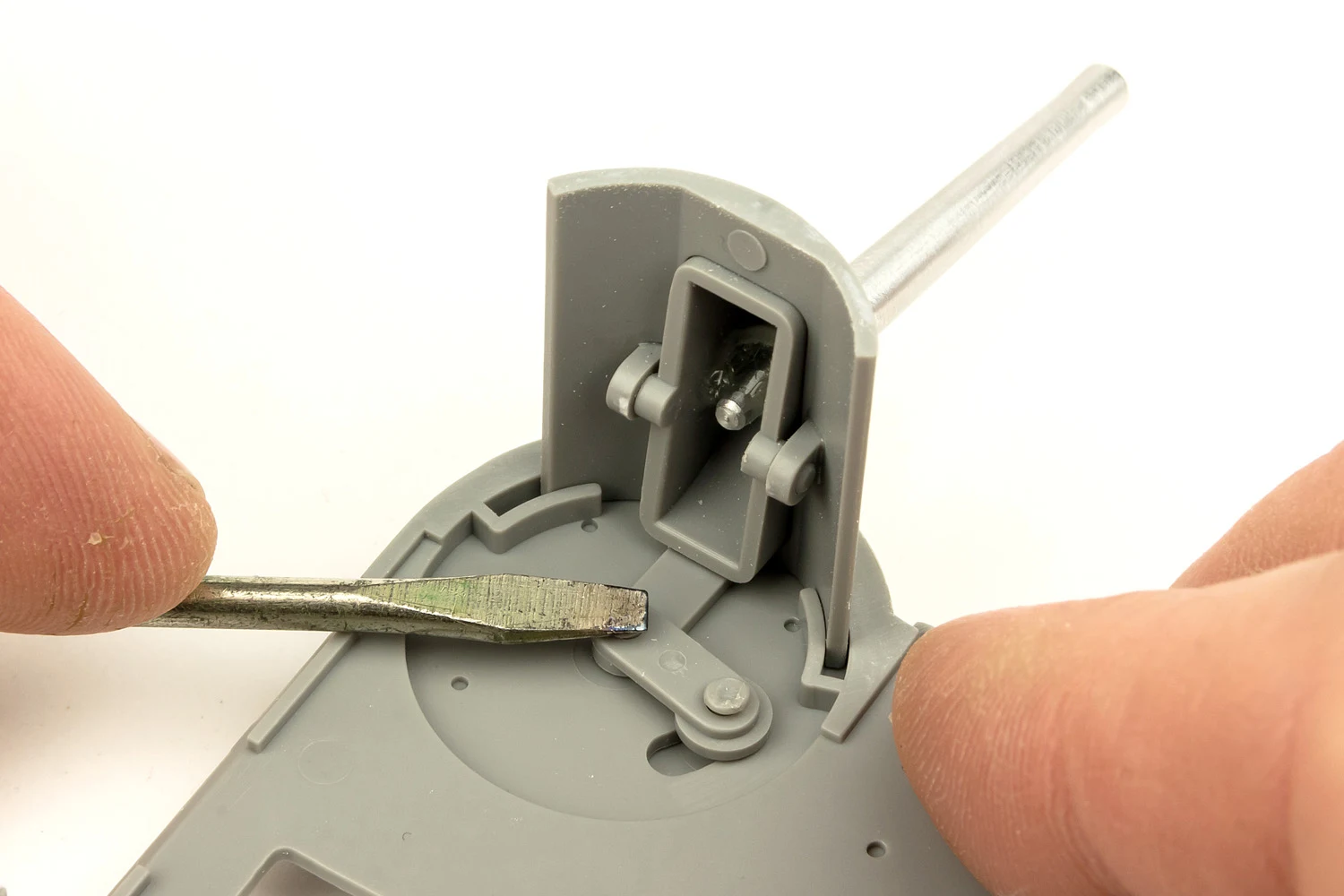

The mantlet and barrel are fitted to the roof plate using a wonderfully old school method. The pins that hold the traverse mechanism in place need their tips melting using a heated screwdriver. I'm sure Takom could have come up with a slightly more practical method for this. Simply gluing a cap on the end of the pin would have worked just as well, but this was a bit of nostalgic fun all the same, reminding me of melting the pins on old Tamiya tank tracks back in the day. Despite all that effort though, I actually ended up gluing the gun and mantlet in place since I wasn't really bothered about them being pose-able.

After a quick test fit, I was having trouble getting the roof plate to fully sit flush on the top of the hull side panels. The problem turned out to be the mantlet, which was slightly too long. Since the bottom edge of the mantlet is hidden behind the armoured surround, it was a simple job to shave a couple of millimetres from the mantlet.

With that done, the roof plate dropped into place with no problems. There were however a couple of small gaps that I was unable to eliminate, one where the front edge of the roof meets the front panel, and on where the rear wall of the superstructure meets the side panel. Both where easy enough to fill though, and given the number of complex angles that make up the hull, I think these small gaps are pretty minor.

The last hull plates to add were the three engine deck plates. Given the fact that all the other plates were now fixed in place, I was a little worried that any previous misalignment would cause problems with fitting these final three. As it turned out, these ones dropped into place without any issues and fitted perfectly, which made a nice end to the main hull construction.

All the smaller details could now be added, such as the on-board tools on the engine deck. I replaced the small solid-moulded tie down loops with thin fuse wire to enable the retaining straps to be added to the tools. The straps were made from thin strips of lead foil.

The base for the radio aerial had the tip cut off and replaced with a short length of aluminium tube. That will make adding the aerial itself much easier.

Takom have done a very nice job with the main crew doors, giving them a fully detailed inner face. Of course, this is a non-interior kit, so if you want to have the doors open you'll need to add a figure in the hatch to hide the empty interior space (or wait for an after-market interior set).

The final details to add to the hull are the two photo-etched headlight guards. Takom have included a small former to help you get the correct curve on the guards, although it's still quite tricky to do.

The former could have done with being a bit thicker to make it easier to hold while bending the photo-etch around it. With care, it does the job though, and the guards look fine once in place.

Moving up to the turret now, and firstly I needed to replace the kit's damaged 37mm barrel with the RB metal one. Like the main 75mm barrel in the hull, this one just needed the hole in the mount drilling a little deeper. Apart from the obvious damage to my example, the kit's gun is actually well up to the standard of the after-market one, so there's no real necessity to replace it if yours is okay.

With the gun sorted, the rest of the turret builds up very quickly, as it's essentially a single piece moulding, to which you add a few small vision ports and the cupola. Since I'd replaced the main armament, I thought I might as well go all out and replace the two 30cal Browning barrels as well. The kit ones are okay, but these turned brass ones with the drilled cooling jackets from RB (set 35B82) really add an extra degree of realism to the model.

With the turret in place, the build is ready for paint. Only the tracks remain to be added, which will happen after the lower hull is painted. All those early concerns I'd had regarding possible fit problems proved to be unfounded for the most part. There were a few small areas that need a little of filler, but given the complexity of the structure, that's hardly surprising.

I'll leave you with a little walk-around of the finished build before it hits the spray booth. The final painting and weathering guide will be coming up soon on TMN, so stay tuned.

In truth I think that Takom have done a commendable job in rendering as much detail as they have, while still keeping the build fairly straight forward and trouble free. It is important to take time while aligning all those hull panels, but as long as you do that, and make sure all the mating edges are properly cleaned up, you should have little difficulty in getting this together.

Andy Moore

Thanks to Takom for sending us this kit for Andy to review and build - expect his painting and weathering of the model to come right here in the next few weeks